Vietnam’s Rise in Precision Tooling: A Look for U.S. Importers

Over the past decade, Vietnam has become a serious contender in the global manufacturing landscape. While the country is well-known for textiles and electronics assembly, one of the most promising growth areas in recent years is precision tooling. U.S. importers looking for advanced, cost-effective manufacturing support are beginning to explore Vietnam’s capabilities in this critical sector.

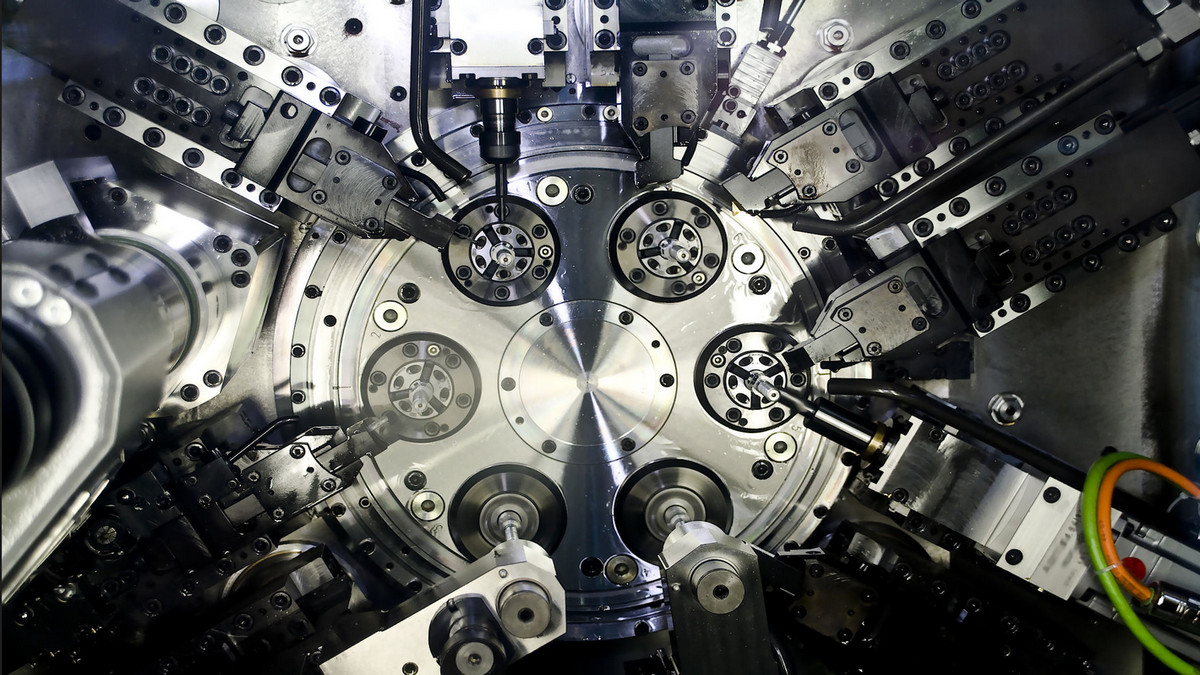

Precision tooling involves the design and production of detailed molds, dies, jigs, and fixtures used in high-volume manufacturing. These tools are essential in sectors such as automotive, electronics, medical devices, and aerospace—areas where accuracy and efficiency directly impact profitability.

Vietnam’s Entry into the High-Tech Tooling Space

Historically, precision tooling was dominated by manufacturers in Japan, Germany, South Korea, and increasingly China. However, due to rising labor costs and geopolitical uncertainties, U.S. buyers are turning to Vietnam as a reliable alternative.

Vietnam’s industrial parks in Hanoi, Ho Chi Minh City, and Binh Duong are witnessing an uptick in tooling workshops and machine shops investing in CNC machinery, EDM systems, and 3D modeling software. These developments are supported by foreign direct investments, especially from South Korea and Japan, who are relocating tooling operations into Vietnam to benefit from lower costs and skilled labor.

When U.S. buyers are sourcing high-precision components, partnering with a bestsourcing agent Vietnam can significantly streamline the process. These agents offer firsthand access to vetted tooling shops that meet stringent export standards.

The Role of Education and Workforce Development

Vietnam’s technical workforce is also advancing rapidly, thanks to government efforts and private training institutions. Technical colleges are incorporating CAD/CAM design and mechatronics into their programs. The result is a growing pool of technicians familiar with ISO-certified practices and digital manufacturing standards.

Manufacturers are increasingly hiring local engineers trained in tool design, reverse engineering, and CNC programming, reducing reliance on expatriate supervision. This trend boosts efficiency and makes local firms more attractive to international buyers.

With the proper oversight, businesses that work with a bestsourcing agent Asia can find highly capable tooling partners while mitigating risk through pre-shipment inspections and supplier audits.

Competitive Edge for U.S. Importers

One of the primary draws of sourcing from Vietnam is cost efficiency. The total cost of tooling production, even when factoring in quality control and logistics, is often 30–40% less than in Western markets.

Moreover, many Vietnamese tooling manufacturers are now offering value-added services, including:

-

Rapid prototyping using 3D printing

-

Design-for-manufacturing (DFM) support

-

Tool validation and testing

-

Maintenance and after-service for exported tools

These services increase the appeal for U.S. importers, particularly those in industries with tight product development timelines. Accessing these benefits often requires experienced local coordination, where a bestsourcing agent Vietnam can play a central role.

Target Industries Benefiting from Vietnam’s Tooling Capabilities

Vietnam’s tooling sector supports a wide array of industries with growing export potential:

-

Automotive: Die casting tools and plastic injection molds for car parts.

-

Electronics: Custom tooling for PCB manufacturing and connectors.

-

Home appliances: Precision fixtures for mold-based parts.

-

Medical devices: Complex tooling for single-use instruments and casings.

U.S. importers in these fields are benefiting from Vietnam’s expanding supply chain network, which includes raw material access, testing labs, and tool surface finishing facilities.

Regulatory and Export Advantages

Vietnam has actively signed trade agreements, including the CPTPP, EVFTA, and RCEP, reducing tariffs and enhancing compliance pathways. Tooling exports benefit from this liberalized trade environment, making Vietnam an attractive sourcing destination from both financial and regulatory standpoints.

This advantage is even more valuable to U.S. importers looking to offset the impact of U.S.-China trade tensions. Tools sourced from Vietnam often avoid Section 301 tariffs imposed on Chinese-made products.

Collaborating with a bestsourcing agent Asia ensures that import documentation, compliance records, and customs clearances are properly managed.

Challenges and Solutions in Sourcing Precision Tools

Despite Vietnam’s rise, some challenges remain. Not all tooling manufacturers operate at the same technical level. There is also variability in material quality and heat treatment standards. Language barriers and timeline mismatches can complicate communications.

To overcome these issues, buyers should consider:

-

Pre-engagement audits of toolmakers

-

Clear design specifications and tolerance expectations

-

Detailed contracts with milestone-based payments

-

On-site inspection prior to shipment

These sourcing strategies can be executed more effectively with the assistance of a knowledgeable bestsourcing agent Vietnam who understands local business practices.

The Future of Tooling in Vietnam

Vietnam is not resting on its current success. National strategies aim to promote high-tech manufacturing, automation, and R&D. Investments into robotics integration, AI-based production systems, and smart factory frameworks suggest that Vietnam’s tooling industry will continue to evolve.

In addition, partnerships with Japanese and European firms are expected to raise technical standards even further. As the market matures, Vietnam may soon rival legacy manufacturing nations in terms of both capacity and innovation.

Final Thoughts

Vietnam’s tooling sector is growing rapidly, with advanced capabilities that can now serve even the most demanding U.S. importers. Precision tooling is no longer limited to established industrial giants. With a strong manufacturing ecosystem, favorable trade agreements, and a rising skilled workforce, Vietnam presents a viable, competitive source for complex tooling solutions.

Importers seeking cost-effective, quality-driven tools should seriously consider Vietnam as a sourcing base. To navigate the local landscape effectively, it is recommended to work with a professional bestsourcing agent Asia who can bridge technical gaps and ensure results that meet global standards.